Project 'Hot gas welding' Research project (completed)

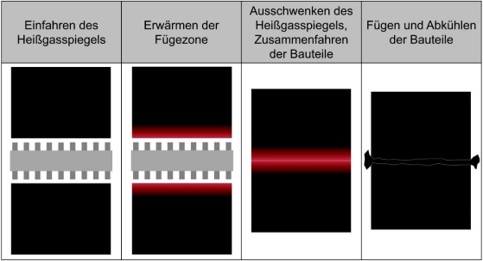

In this research project a new hot gas welding process is being developed and scientifically investigated. The new hot gas welding process has several advantages over currently used welding methods. These are especially in the free design of the weld seam and its course. Three-dimensional weld seams can be produced very easily in comparison to the usual welding methods, such as ultrasonic or vibration welding. In addition, this welding process does not produce any particles which could lead to system damage in the later operation of the components.

The new hot gas welding process is also expected to significantly increase resource efficiency by using air instead of an inert gas. The influence of the gas exchange on the welded joint as well as the targeted, uniform heating of the plastic component in the area of the joining zone is to be investigated. For this purpose, the gas flow and nozzle design must be considered in particular to ensure a fast and uniform heating of the joining zone. Based on the results, design strategies for hot gas mirrors and corresponding component design are to be derived. The resource efficiency of the new welding process is to be confirmed by considering the sustainability.

Duration: April 2019 - December 2021

Project partner: GMB Kunststoffteile GmbH

Funding sign: ZF4166303FH8

Project Management Agency: AiF Projekt GmbH, ZIM-Cooperation Projects

Contact persons: Prof. Dr.-Ing. Matthias Deckert, Johannes Schmid, M.Sc.

Selection of publications within the framework of the project:

Interested? Apply now! for the wintersemester 2025/2026

Get started

find a course