- Static strength test

- Dynamic strength test

- Non-destructive materials testing (ultrasonic measurement, dye penetration and magnetic powder method)

- Metallography

- Experimental stress and strain analysis

- Damage analysis

- Software development for mechanics and theory of strength

- Advice on materials

- Fractography

- Metal analysis

Materials Testing Laboratory (LWF)

Prof. Dr.- Ing. Steffen Greuling

Hochschule Esslingen

Fakultät Maschinen und Systeme

Labor für Werkstoff- und Festigkeitsprüfung

Kanalstraße 33

73728 Esslingen am Neckar

Telefon: +49 (0)711-397-3257 / -3253

Mobil: +49 (0)177-59 78 205

Telefax: +49 (0)711-397-3370

weitere Ansprechpartner

Laboringenieur: Dipl.-Ing. (FH) Udo Merk

Laborwerkstattmeister: Industriemeister Klaus Bendig

Wissenschaftliche Mitarbeiterin: Dipl.-Ing. (FH) Simone Döll-Eberhardinger

Wissenschaftlicher Mitarbeiter: B.Sc. Elmar Schuch

Hardness test

Vickers, Rockwell, Brinell hardness test and universal hardness test

Static strength test

Universal test machines testing forces: 50 - 1,000 kN

Torsion test machine Mt(max): 1.6 kNm

Dynamic strength test

Pendulum impact testing machine (instrumented) 2.5 - 300 joule

Resonating pulsators F(max) from ± 6 to ± 100 kN or Mt(max) to ± 35 Nm

Reverse bending and torsion testing machines Mt(max) from ± 15 Nm to ± 500 Nm

Servo-hydraulic and servo-pneumatic testing machines F(max) from ± 6 kN to ± 250 kN or Mt(max) to ± 2,200 Nm.

Test stand for combined axial, torsion and internal pressure load for multi-axis, phase-shifted and various frequent stresses

(axial ± 125 kN, torsion: ± 4,000 Nm)

Metallography / Microscopy

Cutting, grinding, polishing and etching equipment for sample preparation

Stereo and metallurgical microscopes up to 1,000 x magnification as well as REM up to 24,000 x magnification

Heat treatment equipment

Cooling cabinet, circulating air drying oven and ovens from -80°C to 1,260°C

Experimental stress analysis

Static multi-position measuring system and mobile measurement data acquisition system

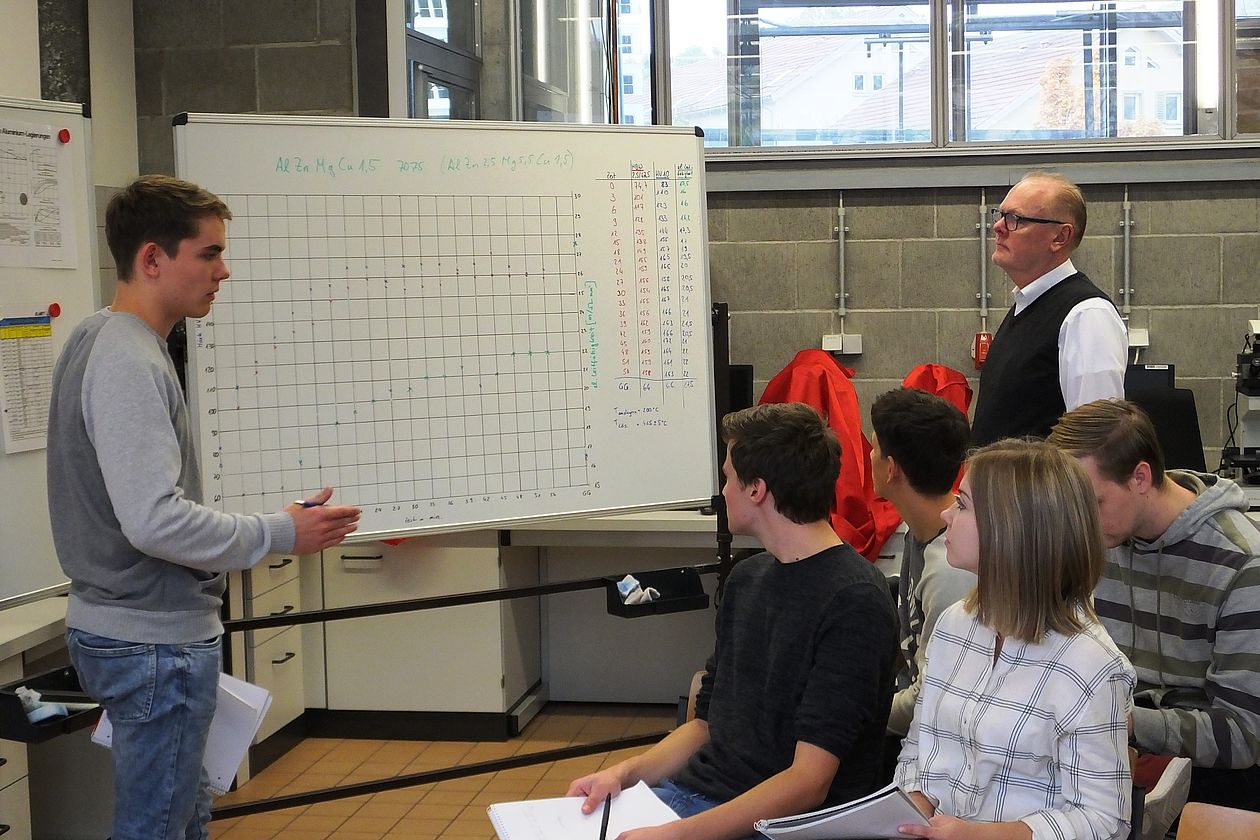

LABORATORIES MATERIALS ENGINEERING 1

- Material characterisation

- Material behaviour

- Experimental determination of strain

LABORATORIES MATERIALS ENGINEERING 2

- Cold forming and recrystallisation

- Hardening of aluminium alloys

- Buckling

- Fatigue behaviour

- Forming characteristics of steel

LABORATORIES COMPONENT SAFETY

- Experimental and analytical fatigue strength analysis

- Stress analysis

- Joining technology

- Non-destructive materials testing (NDT)

- Fracture mechanics

- Determination of a stress-number (S-N) curve (Woehler diagram)

The Materials Testing Laboratory collaborates closely with the industry in Baden-Württemberg. The focus is naturally on the investigation of materials and components for the automotive industry, the ancillary industries and mechanical engineering. The know-how of the professors and the testing equipment are available to all interested companies, however. Scientific investigations are conducted as part of Bachelor theses and projects. The tasks focus on the issues listed below.

- Static and dynamic strength investigations on samples and components

- Experimental stress analysis

- Metallographic examination of the grain structure

- Damage investigations and expert opinions

- Advice on the optimisation of components

- Service life investigation of samples and components under oscillating stress

- Estimation of component reliability

- Working out new concepts for service life calculation

Below are some of the projects which have been carried out recently:

- Service life investigations on bearing shells made from sand and permanent mould casting

- Effect of different jointing processes on the service life of body panels

- Effect of residual stresses on the fatigue behaviour of Al components

- Characterisation of multiphase steels

- Characterisation of high-strength cast iron materials

Industrial partners (selection)

Daimler AG

Robert Bosch GmbH

Dr. Ing. h.c. F. Porsche AG

Festo AG & Co. KG

INDEX-Werke GmbH & Co. KG, Hahn und Tessky, Esslingen

Alfred Kärcher GmbH & Co. KG, Winnenden

Eberspächer Climate Control Systems GmbH & Co. KG, Esslingen

Eberspächer Hochdruck Hydraulik GmbH, Nabern

Baier Consulting,Nürtingen

Mercedes AMG GmbH, Affalterbach

Rücker GmbH, Sindelfingen

Elektror Karl W. Müller GmbH & Co.,Esslingen

JW Froehlich Maschinenfabrik GmbH, Plochingen

Elekromotoren Faurndau GmbH, Göppingen-Faurndau

C. Haushahn GmbH & Co., Stuttgart

HWA GmbH, Affalterbach

Honsel Guss GmbH, Nürnberg

Hydraulik Ring GmbH, Nürtingen

CompAir Mahle, Fellbach

Maschinenfabrik Spaichingen GmbH, Spaichingen

NOE Schaltechnik GmbH & Co., Süssen

Putzmeister AG, Aichtal

RUD Ketten Rieger & Dietz GmbH & Co. KG, Aalen

Andreas Stihl AG & Co. KG, Waiblingen

Micomed Ortho GmbH & Co. KG, Göppingen

Schweizer GmbH Präzidions-Motorenteile, Ostfildern

Technokon GmbH, Rechberghausen

Thyssen Aufzüge GmbH, Stuttgart

Trautwein Engineering, Esslingen

URACA Pumpenfabrik GmbH & Co. KG, Bad Urach

Gustav Wahler GmbH & Co. KG, Esslingen

SEW-EURODRIVE GmbH & Co. KG

ArcelorMittal Germany Holding GmbH

Interested? Find out more! about our degree programmes

Explore now and

find a course