Research and teaching in theory and practice

At CAST, research takes place in close interaction with teaching as well as with partners from industry and the public sector. The focus of the applied research areas lies in the following fields:

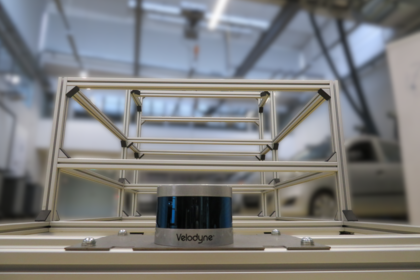

One focus is the experimental automation of the racing team vehicles for an extension of Formula Student towards Formula Student Driverless (FSD). Here, all elements of the signal processing chain of modern AD systems are applied: lidar sensors, video sensors, processing of PCD and image data, training of deep neural networks (DNN, CNN), etc.

Another activity is the construction of a 1:14 scale model traffic landscape, where realistic traffic scenarios are recreated with model vehicles to test and validate autonomous driving functions. In addition to purely sensor-based environment detection, information from a V2X interface can also be integrated.

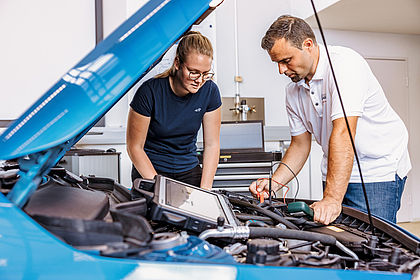

- After sales for electromobility

Many questions regarding the maintenance and repair of battery electric vehicles and those with fuel cells have not yet been widely tested or are answered very differently by the various market participants.

Other research topics such as the diagnostic possibilities and reparability of traction batteries are being investigated in the long term and regularly lead to contributions at conferences such as the EVS (Electric Vehicle Symposium).

- Innovative maintenance and repair concepts

Various combinations of materials, composites and joining techniques are presenting service operations with increasingly diverse challenges in the accident repair of vehicles. In addition to cost-effectiveness, sustainability is increasingly coming into focus, which has an impact, for example, on the selection and implementation of modern maintenance strategies.

- Automotive diagnostics of the future

For the connected vehicle of the future, the further development of diagnostic technology is of crucial importance. The use of high-performance computers is significantly changing the electronic vehicle architecture and requires new communication and diagnostic concepts. By constantly networking the vehicle with the outside world, large amounts of data from the vehicle can be analyzed in the backend (cloud) using machine learning methods (AI). Predictive maintenance and repair concepts are being researched here, and the actual troubleshooting is also taking place through over-the-air software updates if possible.

![[Translate to Englisch:] Testfahrzeug Audi A5 auf der 4-Säulen-Hebebühne (AQUA-Lift), Foto: Hochschule Esslingen/ CAST [Translate to Englisch:] Testfahrzeug Audi A5 auf der 4-Säulen-Hebebühne (AQUA-Lift), Foto: Hochschule Esslingen/ CAST](/fileadmin/_processed_/8/7/csm_LFS_Ausstattung_3_4689afa52f.jpg)