Laboratory work

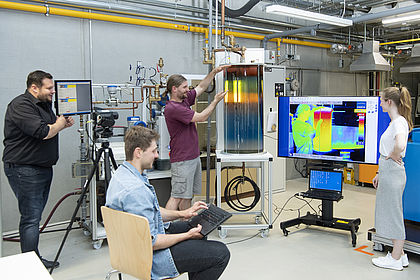

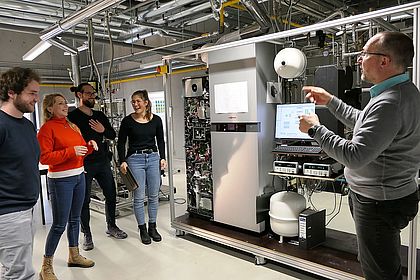

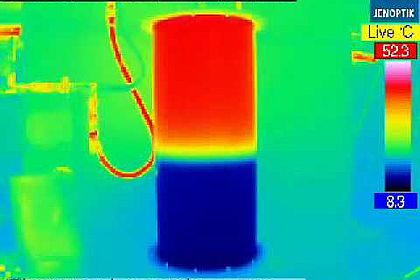

Students conduct laboratory experiments at test benches to learn about important aspects of ventilation and air-conditioning, for example how to determine the level of temperature and humidity recovery of heat recovery systems, fan characteristics, sound power levels of ventilation components, or measure the thermal comfort in rooms.

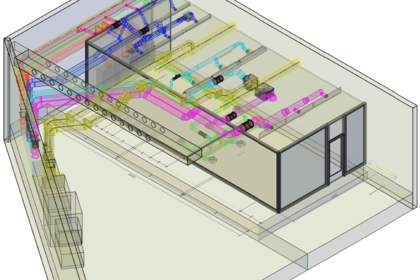

The Ventilation and Air Conditioning Laboratory has the following test benches:

- Freeflow wind tunnel for the calibration of flow-measuring instruments

- Ventilation device with integrated heat recovery test bench

- Calibration vane wheel for thermal anemometer

- Duct leakage test bench

- Ambient air-flow laboratory (due to be completed late 2021)

- Aeroacoustic reverberation test room in accordance with DIN EN ISO 3741

- Fan test bench

- Demonstration wall for domestic ventilation.

The ventilation device and the ambient air-flow laboratory are also incorporated into the lectures on air conditioning. This allows topics such as the design/function of ventilation devices and ambient air-flows to be dealt with from a theory point of view and experienced in practice as well.

Staff

Prof. Dr.-Ing. Karl-Josef Albers (Laborleitung)

Dipl.-Physik.Ing. (FH) Andreas Gauss

Laboratories S15.001 und S15.004 (Hallraum)

Lab phone -3961