Laboratory exercises and projects

Experiments on the roller test stand

The roller test stand is used to conduct laboratory experiments on the performance and torque characteristics of motor vehicles. Performance data measurements involve working out the characteristics of drive motors and assessing the energy efficiency and emission characteristics, where applicable. In driving simulation mode, the test vehicles can be driven under almost realistic conditions on the test stand. Various standardised and in-house test cycles are carried out, further developed where necessary, and compared. Operating strategies are investigated on complex drive trains, e. g. in hybrid vehicles, as project work. The results are then used to improve simulation models, among other things, which can then in turn be validated on the test stand.

On-road testing

To supplement the experiments on the roller test stand, fuel consumption measurements are conducted in on-road tests on real roads or test circuits. The acceleration and braking behaviour of vehicles with and without assistance systems is investigated in experiments on vehicle longitudinal dynamics. The steering performance of vehicles is objectively assessed and discussed with the aid of standardised tests (such as VDA lane-changing test – “elk-avoidance test”, steady-state circular-course driving, sudden steering-angle change...).

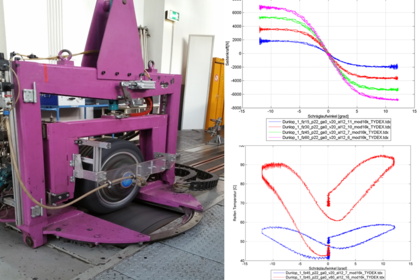

Experiments on the tyre test stand

The lateral force behaviour of tyres on the non-powered wheel is recorded on the tyre test stand. The effects of wheel loading, slip angle, tyre pressure and temperature on forces and moments on the wheel (e. g. the cornering force required to drive through corners), are measured and explained. The findings obtained here are necessary for dimensioning the vehicle, suspension and tyres. The data obtained on the tyre test stand can be used to scale simulation models for vehicle development

Experiments on the vibration test stand/road simulator

The vertical vibration behaviour of a whole vehicle can be investigated on the servo-hydraulic four-poster test rig. The effect of loading, vibration damping and road excitation on comfort and driving safety are recorded experimentally by parameter variation, and analysed. Characteristic parameters and curves of individual chassis components, such as springs or shock absorbers, are measured on component test rigs.

Experiments on the RoadSim 4-poster Mobirex Evo 2 vibration test stand

The servo-hydraulic 4-poster test stand allows the highly dynamic excitation of the wheels of a whole vehicle in order to investigate its vibration behaviour. The main focus is on the vertical dynamics of the car body and the wheel masses. The laboratory experiment therefore involves specifically varying parameters to illustrate the effects of loading, vibration damping and road profiles on comfort and driving safety.

Experiments on component test stands

Suspension components such as shock absorbers, spring elements, assembly mountings and actuators of active systems are investigated on component test stands in respect of their quasi-static and dynamic behaviour, and used to determine characteristic parameters and characteristic curves.

Project work on the driving simulator

As part of setting up and testing the driving simulator, we continually offer group projects which provide practical insight into the technology and possibilities, and the operational processes at a driving simulator. This also includes working with corresponding commercial simulation programmes and models which are used in industry and research.

Experiments on the driving simulator

A driving simulator provides a safe way of experiencing and assessing driving behaviour in extreme driving situations as well. One focus of the experiments will be the visualisation of the car’s steering behaviour and what affects it, for example loading, tyre and axle characteristics and the effects of road or wind excitations. Driving dynamics simulation models, which are compiled in laboratory exercises completed beforehand and assessed objectively offline, can be experienced and subjectively assessed on the driving simulator.