Laboratory staff

Laboratory head

Prof. Dr.-Ing. Gregor Rottenkolber

Deputy head

Prof. Dr.-Ing. Michael Auerbach

Laboratory staff

Location: City Campus Esslingen, building 2

The Vehicle Propulsion Laboratory from the Mobility and Technology Faculty is currently researching ignition sparks for use in hydrogen combustion engines.

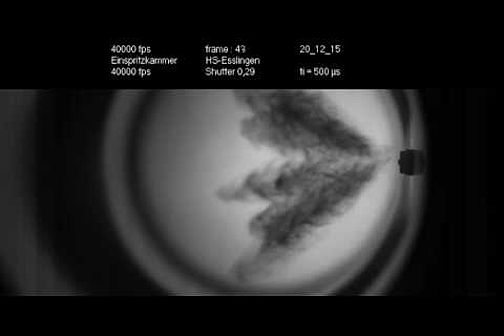

Video 1 shows a spark under the influence of flow.

Video 2 shows a simulation of the velocity field at the spark plug under accelerated oncoming flow. The simulation was performed with AVL FIRE.

The Vehicle Drivetrain Laboratory would like to thank AVL for providing the software for teaching and research purposes.

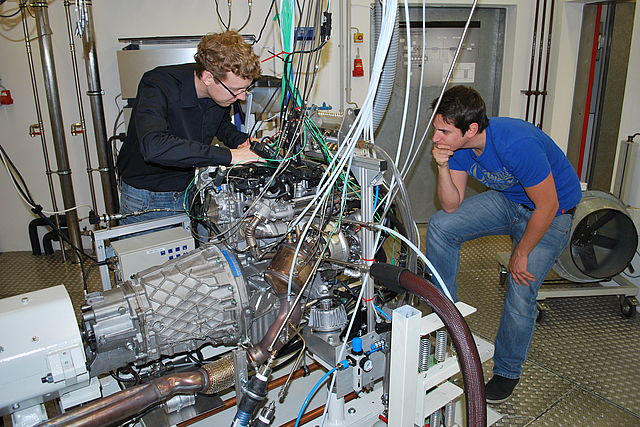

The Automotive Powertrain Laboratory spans a broad spectrum of powertrain technologies which includes combustion engines, electric and hybrid drives with all their subfields.

Its current and future research fields are presented below:

Thermodynamic and optical combustion analysis

The Lab Automotive Powertrain is equipped with modern pressure monitoring systems and precise fuel consumption and emission measurement technology, enabling it to perform detailed thermodynamic analyses. One important tool here is “Miraculix”, a pressure curve analysis tool which has been developed in-house to compile energy loss distributions. The lab also conducts optical investigations into mixture formation and combustion with the aid of high-speed endoscopy.

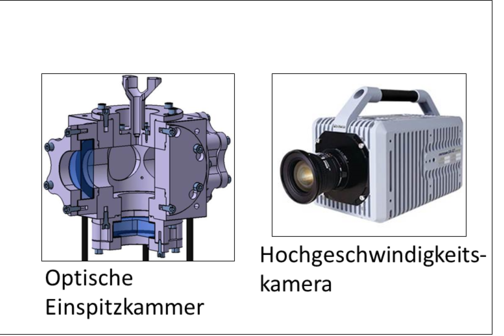

The optical and electric measurement of sprays in a pressure chamber (up to 50 bar) supplements the research carried out on the engine test stands. Just as valuable is the possibility to perform optical analysis of ignition sparks in a heated flow chamber.

Simulation 1D, 3D

The Automotive Powertrain Laboratory not only undertakes experimental analyses but also simulates charge cycle, charge motion and combustion with the aid of the well-known programs GT-Power and STAR CCM+.

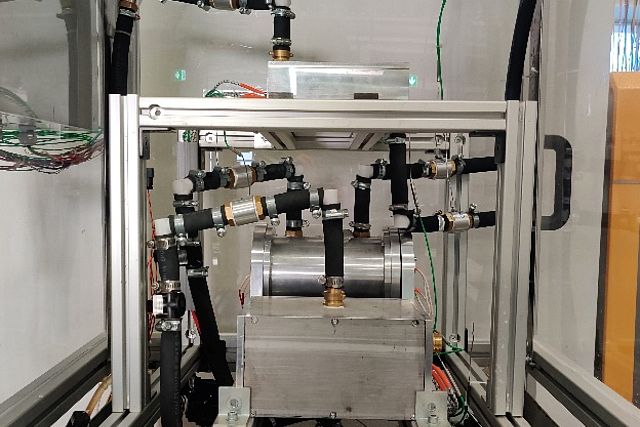

Cooling circuit

This test stand is used to analyse and develop thermal management systems for electrical and electrified drives.

The tasks here are to:

Mechanical engineering workshop

The laboratory has its own mechanical engineering workshop to support the projects carried out there.

The test stand is a compact all-round package which can be used to further develop hybrid and electric powertrains and the associated auxiliary aggregates such as power electronics and cooling circuits. This test stand complements the existing combustion engine test stands and can also handle a very wide range of tasks.

It will also facilitate the simulation of hybrid engine emissions by digitally coupling the drive unit (Dyno 1) to one of the existing combustion engine test stands and tracking a driving cycle driven by the e-drivetrain test stand with the combustion engine.

The goal is to create a hydrogen test stand in the Automotive Powertrain Laboratory. The concept phase will be undertaken by students, and they will also bring the project to fruition.

Laboratory work in the Bachelor degree programmes:

Laboratory work in the Automotive Engineering Master programme:

Student projects and final theses:

Project work is undertaken in the 4th and 6th semesters. The Lab Automotive Powertrain regularly advertises projects which it supervises itself.

The Lab Automotive Powertrain also supervises projects and final theses which form part of the Master programme:

Power classes

- 350 kW/800 Nm

- 220 kW/525 Nm

- 150 kW/340 Nm

2 HORIBA Mexa 7170DEGR for exhaust emission components CO, CO2, NO, NO2, N2O, Total HC, CH4 and O2 as well as EGR rate

- Photron SA-X2 high-speed camera

- Storz endoscopes

- AVL FuelExact

- AVL 733

- AVL Smoke Meter 415S

- MS4 Pegasor Particle Sensor

- AVL Opacimeter 439

- 2 FEV FEVIS (16 channels)

- 1 FEV CAS (8 channels)

- Sensor system Kistler/AVL

- AVL 442

- Intake air, charge air, cooling water and engine oil

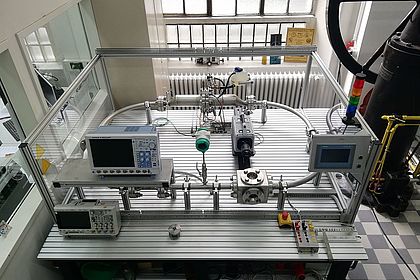

- Ignition test stand

- AVL XION (8 channels)

A complete list with all research work, research contributions and publications since 2008 is available on the German website.

Get started

find a course