Project 'NanoTool' Research Project

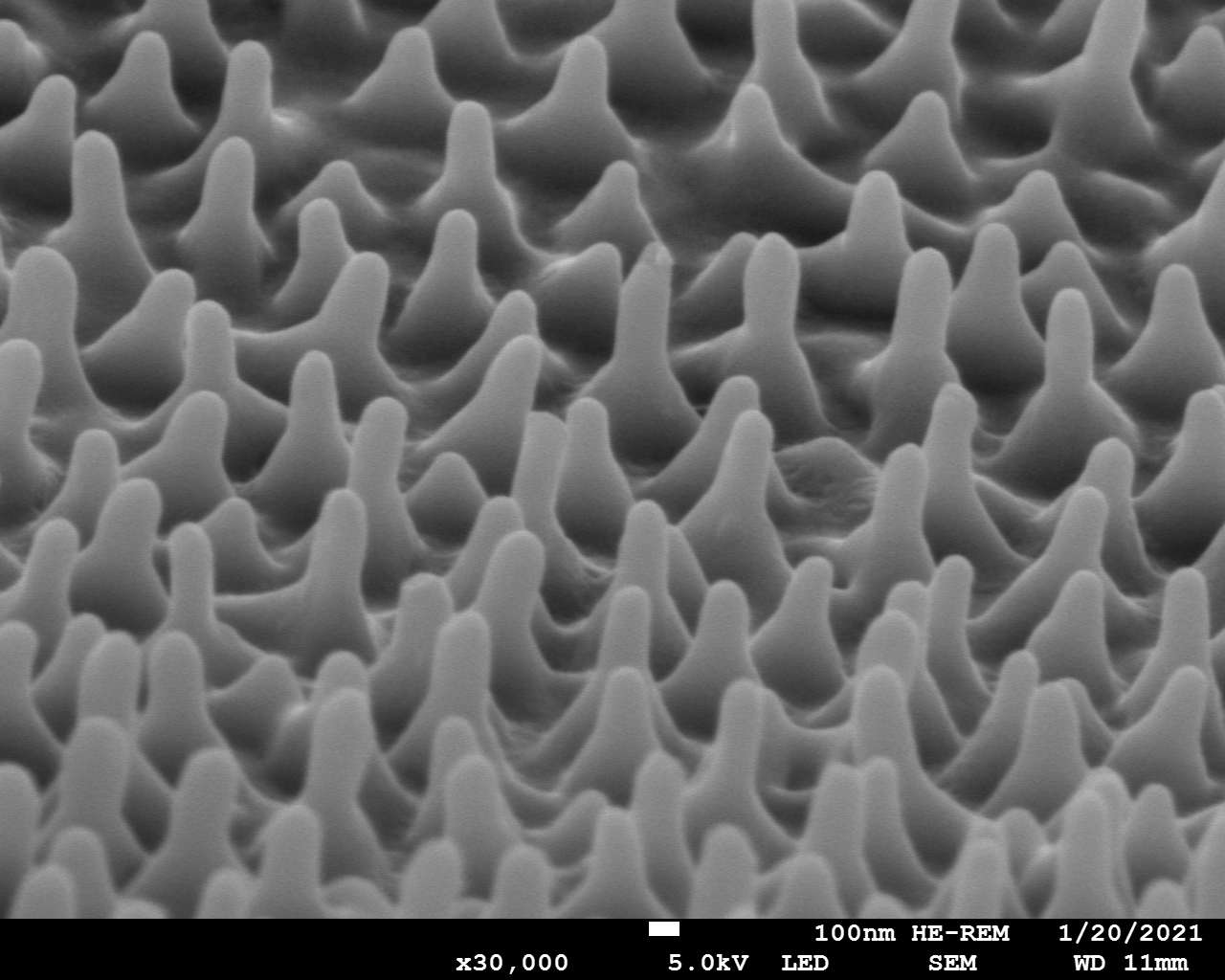

NanoTool: Development of a 3D model with water- and dirt-repellent nanostructure with contact angles >160°, development of a method for researching dirt-repellent properties of nanostructures and researching component properties.

The project objective is the development of a water- and dirt-repellent nanosurface, which is to be engraved for the first time as a negative into the insides of injection mold (SGW) mold insides by means of picolaser in order to produce individual workpieces (e.g. ABS, TP, TPE) with self-cleaning properties. For this purpose, superhydrophobic (contact angle > 160°) surfaces (e.g. lotus flower or cicada wing) will be researched and a 3D model developed on them. Using a high-precision (accuracy< 1 µm) laser micromachining machine, a process is to be developed to engrave this nanostructure with an agreement of > 99 % on the inside of the mold, which will then be inserted into a specially developed injection molding tool with near-contour temperature control. By means of the novel temperature control system, the injection mold will enable a homogeneous (+/- 1 °C) injection temperature and a heating rate of up to 60 K/s. The new variothermal temperature control system will be used for this purpose. For this purpose, a new variothermal process control will be developed to ensure a moldability of > 95% of the nanostructure onto the workpiece. The resulting workpieces should exhibit water- and dirt-repellent properties over the entire product life cycle (> 5 years).

Duration: July 2022 - June 2024

Project partners: LMB Kunststofftechnik GmbH; Laser-Mikrotechnologie Dr. Kieburg GmbH

Funding code: KK5052610 FF1

Project Management Agency: AiF Projekt GmbH, ZIM Cooperation Projects

Contact person: Prof. Dr.-Ing. Matthias Deckert, Dennis Weißer, M.Sc.

Interested? Find out more! about our degree programmes

Explore now and

find a course